If you’ve shopped for tires, especially heavy duty tires, you’ve probably heard of bias ply tires before. You may even know it has something to do with the tire’s construction. But what is a bias tire, exactly? Well don’t worry, because I’m here to tell you!

Plies

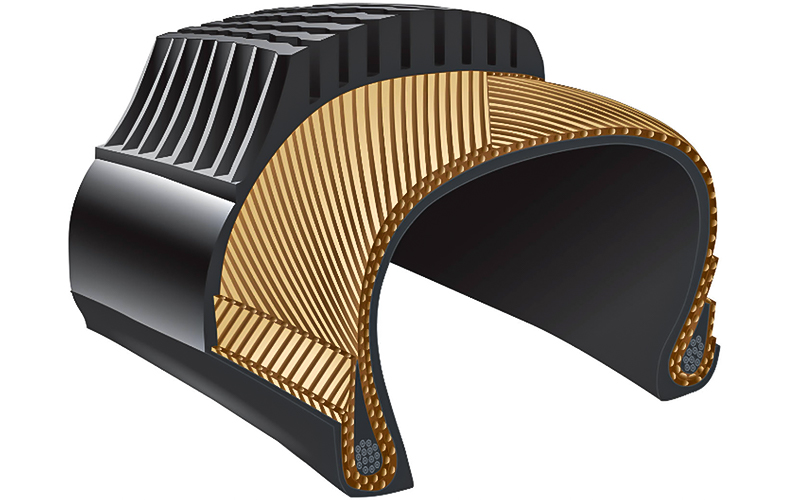

First of all, let’s talk about plies. They play a big part in tire construction, so to understand a bias tire, you should know what a ply is. So what is a ply? To put it simply, plies are the internal layers of the tires. As we talked about before, tires aren’t just solid hunks of rubber, they’re made of many components, and plies are an important one. These are what gives the tire its shape and durability, as well as its rolling resistance and much of its capability.

As for the plies themselves, they can be made from a variety of materials, such as thin steel cables, nylon, kevlar, or other durable textile materials. These are inlaid with and fused together with various rubber compounds into one piece, and the resulting sheet is the finished ply.

So What is Bias Construction?

The main difference between the tire construction types is really how the plies are laid out, although the cord materials can differ as well. Bias tires are, as the name suggests, constructed with the plies on a bias (or a slant). This means that the plies are criss-crossed across the tire from one bead to the other, usually at a 35 to 40 degree angle to the center line.

So what difference does this make? Well, for one thing, the tire is less flexible as a whole. That’s because in this construction, the sidewall and crown plies are not separate, and you end up with a thick ply layer all over the tire. However, this also means these tires are pretty tough and resistant to punctures (one reason they’re great for heavy equipment).

As with everything, though, this construction has its pros and cons. So let’s take a look:

Pros

- Tough construction and strong sidewalls

- Great for rough terrain or for trailers/heavy loads

- Rolls straight when towed

- Cheaper than other constructions

Cons

- More prone to overheating (due to thicker layers)

- Does not absorb bumps (all the sidewall flex is transferred to the tread, since it’s one piece)

- Increased slip due to flexing deforming the footprint.

- Poor rolling resistance

Belts

Some bias tires are constructed with belts as well. This started around the late 1960s, when bias tires were still the norm. European-made radial tires started to gain popularity in the muscle car circuit, due to their longer life and smoother ride. So, to compete, the American companies making bias tires came up with a solution: belts.

After the plies are laid out, an extra layer of belts were added to the tire in the construction process. These belts were usually made of steel or some other corded material, and they were laid out at differing angles above the ply layers. This simple solution served to stabilize the tread (which was added on top), providing a smoother ride and a lower rolling resistance without having to change the entire tire construction process.

By the 1970s, radial construction took over anyway, but you can still find belted bias ply tires today. They’re excellent for classic cars, especially if you want to get as close to original as possible while still having a nice ride.

Login and Registration Form